By contributing author: Simerjeet Virk – Assistant Professor and Extension Specialist in the area of Precision Agriculture and Machinery Systems at the University of Georgia

The increased focus on improving application accuracy, placement, and timing of crop inputs is driving the growth and development of new technologies in agriculture. With the availability of multiple precision ag technology options today for growers, it is important to understand where and how technology can help growers in being more efficient with crop inputs while also increasing productivity and profitability at their farm. To evaluate some of the new planting and spray technologies available today, we are conducting several research projects this year at the Darrel Williams Research Farm at the Sunbelt Ag Expo.

One of our research projects is aimed at evaluating the functionality and capabilities of an advancing planting technology called SmartDepth from Precision Planting. SmartDepth replaces standard mechanical depth setting on planter row units with an electronic actuator that can be adjusted and programmed from the planter display. This technology, when combined with Precision Planting’s SmartFirmer, which senses several soil properties including moisture in the furrow while planting, can be utilized for making both manual and automated depth adjustments during planting so that seed can be placed at the appropriate depth where adequate soil moisture is present for timely germination and uniform emergence. In some cases, this technology can also be used to plant at a shallower depth when field conditions are too wet. While this SmartDepth technology has been around for a couple of years now and is primarily used in corn in the midwestern US, we are investigating how it can be utilized in the primary row crops grown in the southeastern US. We are testing this technology in cotton, peanuts, and corn at the Expo Farm this year by performing multiple automated depth adjustments in the field while planting each crop and collecting different in-field measurements to see how well the technology works and how it can help in making better planting decisions, especially when the fields are dry or too wet.

Figure 1. Precision Planting SmartDepth unit (left) and 20|20 SeedSense display (right) used to program and control depth adjustments on the planter row units.

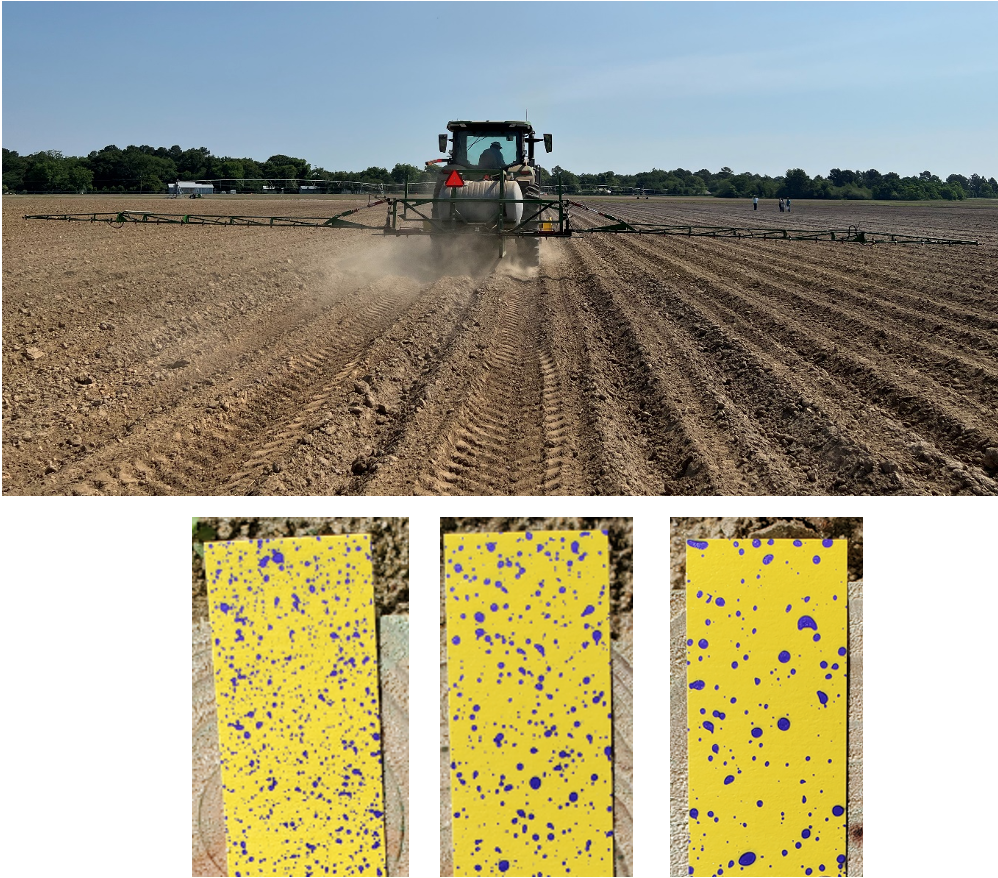

The other project focused on spray technology and application parameters is the continuation of the research from last year where we are comparing spray coverage and pesticide efficacy at different spray volumes and nozzle types. The main difference between all three nozzles – at a given spray volume – is the droplet size which is an important application consideration as it affects both coverage and off-target movement. We have advanced spray technologies available now which can target a specific droplet size along with application rate (spray volume) during pesticide applications. Minimizing spray drift while maximizing pesticide efficacy to improve spray application accuracy and placement is important so we are investigating how growers can utilize some of the available spray technologies to maintain optimal application parameters for effective and safe pesticide applications.

Figure 2. Row-crop sprayer (top) and spray deposition on water-sensitive paper (bottom) showing differences in droplet size and coverage among the three nozzle types used in the study.

For more information on any of these studies or to take a closer look at ag technologies used at the Expo Farm, plan to visit the precision ag stop at the Sunbelt Ag Expo Field day on July 21st. Details regarding Field Day can be found at sunbeltexpo.com/field-day.